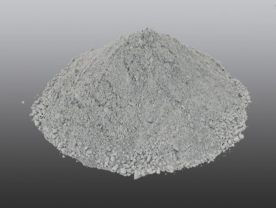

CalciumAlumina Cement

Applications

CalciumAlumina Cement is mainly used as a combination of refractory pouring and refractory spraying materials. There are two main requirements for ordinary aluminum calcium acid cement:

(1) Appropriate condensation time to ensure sufficient operating time. Generally, the first condensation is greater than 1h and the final condensation is less than 8h.

(2) In sufficient early intensity, it can reach 60%~ 70%of the strength specified by the cement marker for one day, and the maintenance can reach more than 90%.

In addition to the above two points, the calcium pure aluminum cement also requires a certain amount of fire resistance and good operating performance to meet the construction requirements and high temperature usage requirements.

Medium and low grade refractory castables, such as clay and high aluminum castables, use ordinary calcium aluminate cement as binder. High-grade refractory castables such as rigid jade, mullite, chrome-containing rigid jade, corundum – spinel castables are made of pure calcium aluminate cement as binder. The addition amount of ordinary refractory castable calcium aluminate cement is 10%~20%, the addition amount of low-cement refractory castable is 5%~7%, and the addition amount of ultra-low cement castable is less than 3%.

Among the irregular refractory materials, the pouring materials for binding agents with aluminumite cement are widely used.

(1) The use temperature of clay watering is 1300-1450 degrees. It is generally used as a steel heating furnace. Various thermal treatment furnaces, boilers, vertical kiln and rotary kiln lined.

(2) The use temperature of high aluminum pouring materials is 1400-1550 degrees, which can be used for various thermal treatment furnace lining and burning mouth. Electric furnaces, high -temperature sections of lime vertical kiln, rotary kiln head, and power plant boiler lining.

(3) The use temperature of Gang Jade Water is 1500-1650 degrees, which is mainly used in the lining body of various high temperature furnaces and high-temperature components to buy steel water vacuum-proof devices. Line, lining in the top triangular area of the electric furnace, LF furnace cover, and the high temperature wear -resistant lining of the petrochemical industrial catalytic cracking reactor.

Specification

| Compound | Specification |

| Specificarea | 576 m/kg |

| Time of coagulation | |

| The first | 279 minutes |

| Attheendof | 311 minutes |

| Rupture strength | |

| 1d | 11.2 Mpa |

| 3d | 12.3 Mpa |

| Compressive strength | |

| 1d | 65.8 Mpa |

| 3d | 75.1 Mpa |

| Chemical component | |

| Sio2 | 0.58 % |

| Fe2o3 | 0.23 % |

| Al2o3 | 69.12 % |

Packing

25kg/bag,1 ton/bale

Storage: Preserve in well-closed, light-resistant, and protect from moisture.